Protecting your workers from a fall means never leaving anything to chance. Every element of your fall protection or prevention system must be chosen with care. When you build the right system, you can have confidence that your workers will be safe before, during, and after a fall occurs.

In this guide, you will learn why anchors are an important part of fall protection, how to find the right equipment for your work, and how to use anchors to keep your employees safe in any industry.

Key Takeaways

- Understand what an anchor in fall protection is and how to differentiate between the many terms used for this equipment.

- Learn about the different types of anchors, what they are used for, and when to use an anchor for workplace safety.

- Get step-by-step instructions for choosing the right anchor for your application and jobsite.

- Find answers to common questions about anchors, including inspection best practices.

Table of Contents

Glossary of Terms

Anchor

Anchor is a common name for an anchorage, anchorage connector, and/or anchor point.

Anchor Point

Anchor point is another common name for an anchor.

Anchorage

An anchorage is the structure that the anchor or anchorage connector attaches to. These structures vary depending on the industry, type of work, and jobsite. An anchorage in a warehouse may be a beam, for example, while the anchorage on a residential construction site could be the roof.

Anchorage Connector

Anchorage connector is the piece of equipment that connectors the worker’s fall protection system to the structure or anchorage. These devices vary based on application and jobsite. These are the products that you buy from fall protection equipment manufacturers.

Anchorage Tie-Off

Anchorage tie-off is another term for anchors, anchor points, and anchorage connectors. You will typically hear this term used for anchors used in a fall restraint system.

What is the difference between an 'Anchorage' and an 'Anchorage Connector'?

Anchorage refers to the structure used as the base for your fall protection system while anchorage connectors are the devices you use to connect your worker to this structure. It’s important to make this distinction because both components play an essential role in fall protection.

For example, let’s say your Competent Person tells you that your anchorage connectors are capable of handling 5,000 lb. of force. If you don’t understand the difference between anchorages and anchorage connectors, you may think that this means that the structure at your worksite is capable of holding this weight. You may then use an anchorage with a much lower weight capacity, putting your workers at risk if they fall.

When discussing fall protection anchors, many people confuse or conflate these two terms, so it’s important to check for this mistake. Always rely on your Competent Person to approve the correct installation of your anchorages, as required by OSHA. You may also reach out to a manufacturer, such as FallTech to determine the application’s suitability.

What is a Fall Protection Anchor?

Generally, the term “fall protection anchor” refers to the combination of anchors and anchorages that connect workers to the worksite. The types of anchors you use and the anchorages you attach them to will vary depending on your industry, the specifics of the jobsite, and the type of work you’re doing.

On a roofing site, for example, you may use a roof anchor to connect workers to the residential building they’re working on. On a larger building, workers may use a tie-back SRL or lanyard that is designed to wrap around a beam and tie back to itself. Since the anchorage connector is built into the lanyard, this type of equipment is sometimes called an anchorage system.

The reason you’re using this gear is also relevant. Anchors used for fall restraint won’t be subject to the same amount of force as those used for fall arrest systems, so the requirements are different depending on the application.

What is a certified vs. non-certified anchor?

There are two main factors that differentiate certified and non-certified anchorages: the load they can bear and who has approved the structure for use as an anchorage.

According to ANSI Z359.14, anchorages can only be certified if they’ve been approved by a Qualified Person. Once the Qualified Person has evaluated the anchorage, confirmed that it meets the required load capacity, and documented their findings, it can be used as a certified anchorage.

If your Qualified Person isn’t available, a Competent Person can search the job site for a structure that meets the load capacity requirements for a non-certified anchor. If the structure passes the Competent Person’s visual inspection, it can be used as a temporary anchorage. Until your Qualified Person can evaluate it properly, however, it can’t be certified.

What is an Acceptable Anchorage Point in a Fall Protection System?

Your Qualified Person will help you determine an acceptable anchorage at every new location. Some sites may provide anchorages that are already designed to accept a lanyard or anchor. If not, your Qualified Person will find the best place to use your anchor devices for maximum safety.

Acceptable anchorage options are:

- Ideally located directly above the worker, which reduces free fall and swing fall distance. It also reduces the minimum required fall clearance (MRFC) requirements you have to meet.

- Evaluated and approved by a Competent Person and/or Qualified Person.

- Never used for any other operations.

- Compliant with OSHA standards, which requires the anchorage strength to be twice the likely load it will have to support during a fall.

Along with determining if a structure is a safe anchorage option, your Qualified Person will decide which type of anchor is best and most safe to use with it. A penetrating anchor, for example, is required for installation directly into a structure using nails, screws, bolt, or other fasteners. A non-penetrating anchor, on the other hand, does not deface the structure. Follow their exact recommendations on which products to use and where to attach them.

Types of Anchors

Your Competent Person will use several factors to determine which anchor is best for your work zone based on the certification of the anchorage by a Qualified Person or Professional Engineer. As mentioned, the capabilities of your anchorage will influence the type of anchor you can use. Whether you need to arrest falls or use a restraint system to prevent them will also be a factor.

One of the most important considerations is the type of substrate your anchor will attach to. The different categories include:

- Steel

- Concrete

- Roofing

- Multi-Use

- Specialty

Within each of these categories, your Qualified Person will also decide if a penetrating or non-penetrating anchor point is needed. Your fall protection system’s effectiveness relies on using the appropriate equipment for each situation, so rely on their expertise to make the right decision.

Steel

Products shown above: 7712 | 7414 | 7711 | 7408 | 7530

Products shown above: 7712 | 7414 | 7711 | 7408 | 7530

These anchors are designed to attach to steel structures, such as the frame of a building. Some of the common types of steel anchors include:

- Fixed D-ring Anchors - You can choose a bolt-on anchor that you can screw directly onto the structure or a bolt-on plate anchor that includes an anchoring plate that can be attached to the structure.

- Beam Clamp Anchors - If you want the ability to change the position of your horizontal I-beam anchor point, you can use a clamp that locks onto the beam. You can also find I-beam clamps that can be permanently installed on the anchorage. Some beam clamps are also suitable for attachment to vertical members.

- Beam Trolley Anchors - You can also use trolley anchors to give your workers the freedom to move horizontally below the beam. These anchors include wheels that allow the device to slide on the overhead beam while still protecting against falls.

- Wire-form Anchors - When you temporarily need to anchor workers to a round overhead structure, such as pipe racking or scaffolding, you can use these anchors.

You can also use movable eyebolts and swivel rebar hooks for temporary anchors on steel structures.

Concrete

Products shown above: 7451C | 7443 | 7452AC | 7448L | 7451AC

You may need concrete anchors in a variety of situations. Depending on the structure, you may need to scan the area before installing your anchor to avoid hitting rebar. Common concrete anchors include:

- Wedge anchors - Push these anchors into pre-drilled holes in the concrete. When you release the spring-loaded anchoring system, it securely attaches to the sides of the hole. This anchor can be removed and used in other locations.

- Pour-in-place web anchors - You attach these strap anchors to rebar before pouring the concrete. These temporary anchoring devices are made to resist abrasion that may occur during use after the concrete sets. When work is finished, simply cut the webbing to remove.

- Rotating D-ring anchors - Anchored into cured concrete with expansion bolts or concrete screws, these devices offer 360° rotation to give workers more mobility.

Roofing

Products shown above: 7432 | 78012WCSWE | 7410 | 7395C | 7434S

Roofing anchors are made specifically for work on residential and commercial roofs. Common types include:

Since roofs may be wood or metal, check your anchors to ensure that they are made for the surface you will be working on.

Multi-Use

Products shown above: 7218LT | 7428 | 7372 | 74946 | 7214

Products shown above: 7218LT | 7428 | 7372 | 74946 | 7214

Some anchorages have similar requirements. In these cases, you can use a multi-application anchor to secure your workers. You can find options such as:

- Sewn Web Anchors - These devices are available in either pass-through styles, where you wrap the anchor around the anchorage and through a second D-ring on the strap, or choker styles, where you wrap the device around the anchorage and through a cinch loop. Both are durable and lightweight.

- Cable Sling Anchors - You can loop these anchors around the anchorage for a secure attachment, particularly when you’re concerned about sharp edges.

- Suspended, Drop-Through Anchors - If you need to install the anchor through an overhead opening in concrete, grating, or steel deck, this device is an ideal option.

Multi-use anchors are often a great choice for applications involving heat, welding spatter, sparks, and arc-flash. The anchor’s material determines its suitability for these situations, so rely on your Competent Person’s recommendation.

Specialty

Products shown above: 7445 | 7465A | 7460A | 7495K

Products shown above: 7445 | 7465A | 7460A | 7495K

Some applications, such as window cleaning, require specific types of anchors. For these situations, you will need one of the following:

- Strut Anchors - When workers need to move horizontally along overhead struts, these anchors are the answer. Easily install these devices and move them to new locations when needed.

- Parapet Anchors - You can clamp these anchors onto parapets and approved guardrail anchorages for quick and safe use.

- Window and Door Jamb Anchors - If the windows and doors aren’t installed yet in a building, you can use these devices for temporary attachments to these spaces.

- Rail Anchors - Workers on elevated train trestles and rails can use these anchors to move securely along the rails without risking their safety.

Penetrating

For each of the above categories, the available anchorages may require penetrating fasteners. You will need to install your anchors directly into the anchorage, penetrating the structure to create a secure attachment.

Non-Penetrating

Some worksites may allow you to attach anchors around structures, rather than into the substrate. These devices use friction or a device wrapped around the anchorage to support the worker. If you can use an anchor with a clamp, pass-through or choker style, cable sling, or interlocking plate design, you won’t need a penetrating device. Mobile anchors, such as beam trolleys and counterweight systems, are also non-penetrating options.

Basic Components of an Anchor

Since there are so many different types of anchors, these devices vary widely in design. That said, every anchor shares a few basic components.

First, every anchor must include a connection point where you will connect the lifeline or lanyard to the device. Most often, this connection point will be a D-ring or an O-ring. You may also find anchor points that use a carabiner or interlocking plates to secure the connector to the anchor.

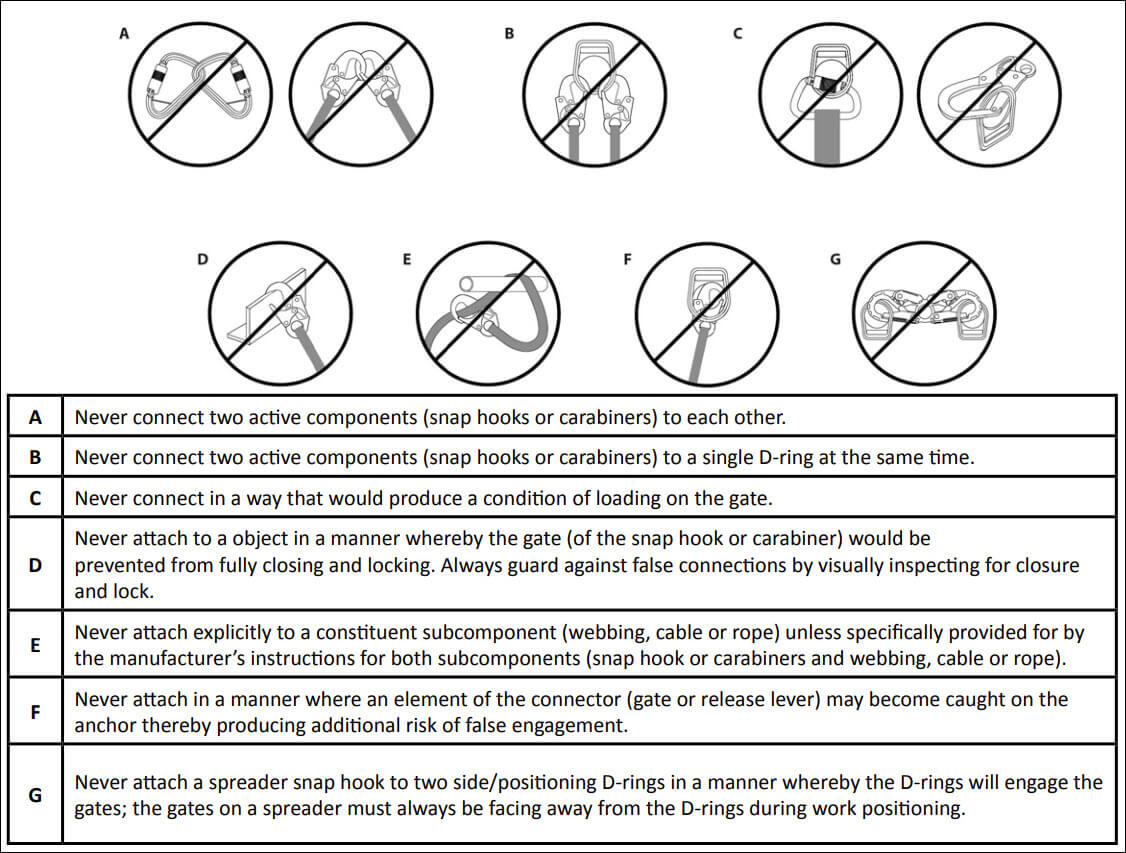

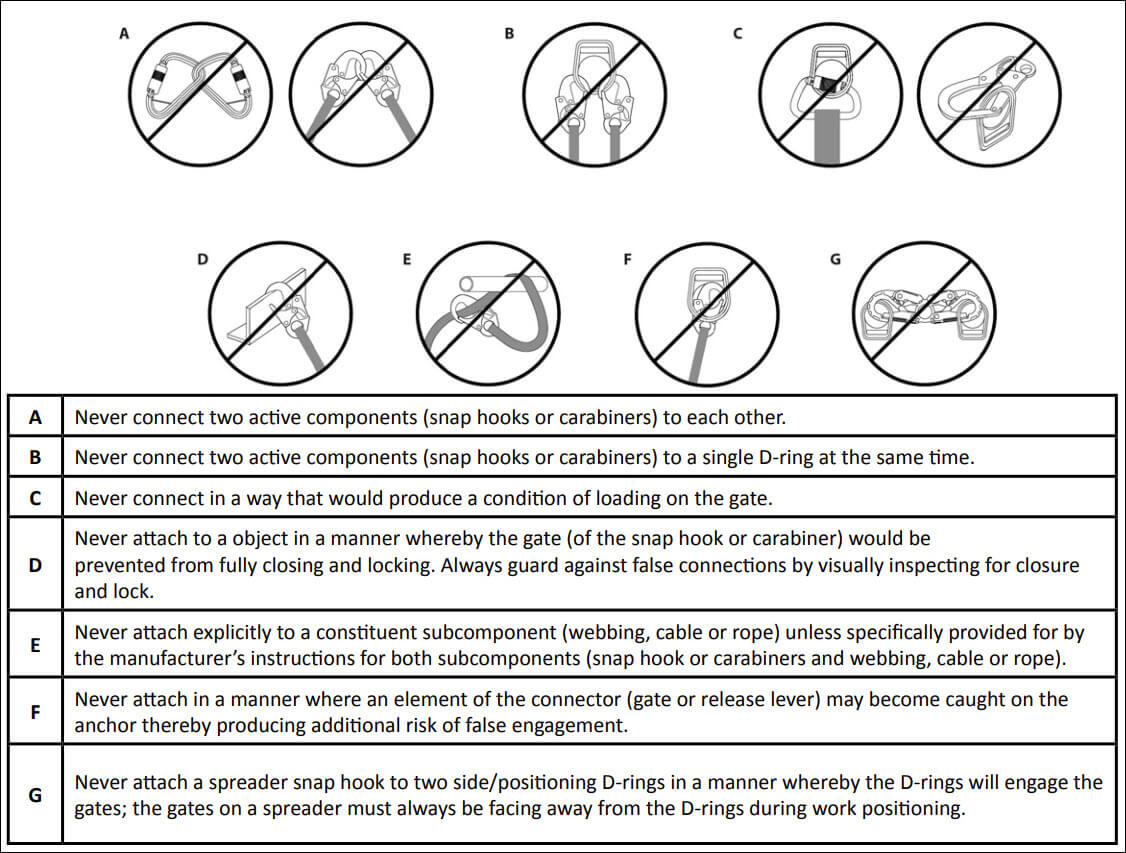

These components must enable a clean and compatible connection point. For example, the connector (D-ring or O-ring) must be larger than the snap hook on the lanyard or lifeline. You can see which connections are incompatible and dangerous to the worker in the diagram below:

When Should You Use a Fall Protection Anchor?

Whenever your workers need a fall protection system, such as working at a height, you need an anchor. This includes both active and passive systems, though most situations that include an anchor fall under active fall protection efforts.

Before using an anchorage, ensure that it is rated for the application you are using. An anchorage rated for work positioning may only meet the lower static load requirement of 3,000 lb. rather than the 5,000 lb. requirement for fall arrest anchorages, so it may not be able to handle the force of a fall. You should always check with your Qualified Person before using any anchor or anchorage. An anchor that is already in place at a jobsite may not be rated for fall arrest, so never assume that an anchor is safe to use until you’ve been given approval.

It’s also important to note that you can only use one anchorage per user. No matter the size, you can’t connect multiple workers to the same anchorage connector.

Choosing a Fall Protection Anchor

To fully protect workers at any jobsite, use the anchor that is best suited for that situation. Unlike most fall protection equipment decisions, where you choose your gear based almost completely on application, the conditions at the location will largely determine which anchors your use. In this section, we’ll show you how to find the devices that will protect your workers at your next project. Along with these steps, you should use your Qualified Person’s advice when purchasing your fall protection anchors.

Step 1: Identify the application

Anchors used for fall restraint and those used for fall arrest have different requirements. If a worker falls, the anchor needs to withstand the forces created by the fall. Because of this, fall arrest anchors must be able to withstand 5,000 lb. of force or twice the maximum arrest force. Work positioning anchors, on the other hand, have a capacity requirement of only 3,000 lb. or twice the amount of foreseeable force.

It’s critical to remember that these capacity requirements apply to both the anchor, or device that you are bringing to the site, and the anchorage, or structure, that you are attaching your fall protection system to. If one of these components doesn’t meet these standards, you won’t be able to confidently ensure safety.

Step 2: Evaluate the anchorage

When you have a new location for an upcoming project, your Competent Person will need to visit the site in person. They will locate any fall hazards and determine the type of fall protection system you will need to maintain safety. During this inspection, the Competent Person will determine which structures may be used as anchorages. The Qualified Person will then determine if the structure can hold the appropriate loads for the application.

Step 3: Choose the right anchor

Once they know which anchorage you will be using, your Qualified Person will inspect it to see what kind of substrate it is made of. As mentioned, knowing which type of substrate you’re dealing with is essential to choosing the right device. Once they have this information, the Qualified Person can then decide what type of anchor will work best for these conditions. They will also consider other factors, such as the type of work you’ll be doing, if workers need the ability to move around, and if it would be better to use a temporary or permanent anchor. Based on this information, they can choose the device that will work best for that job.

Step 4: Determining anchor needs

Along with choosing the right type of anchor for the substrate, you will also need to determine if you need a penetrating or non-penetrating anchor. Some substrates, such as steel beams, don’t allow for penetrating anchor points. Others, such as many roofs, can only be used with penetrating devices. Your Competent Person will determine which option you need during their inspection.

What Should You Look for When You Inspect Your Anchor?

Regular, thorough inspections are a key part of fall protection. Your equipment may be damaged in the field, because of improper storage, or after years of use. The only way you can be sure that your safety systems are working correctly is through proper inspections. Before every use, workers should do a pre-use inspection to check for any problems. Your Competent Person must also inspect all of your equipment at least once annually. Also, consult the user manual for the manufacturer’s recommended inspection schedule and frequency.

Regular, thorough inspections are a key part of fall protection. Your equipment may be damaged in the field, because of improper storage, or after years of use. The only way you can be sure that your safety systems are working correctly is through proper inspections. Before every use, workers should do a pre-use inspection to check for any problems. Your Competent Person must also inspect all of your equipment at least once annually. Also, consult the user manual for the manufacturer’s recommended inspection schedule and frequency.

When inspecting your anchors, you should always start with the user manual. Different types of anchors have different inspection requirements, so follow the manufacturer’s recommendations. You can also contact the manufacturer directly if you have any questions.

With that said, there are some basic components that you should inspect on every anchor.

Labels

Check the labels to ensure they are intact, legible, and undamaged.

Anchor Materials

Rope & Webbing

Inspect anchors with webbing by checking both sides of the device and bending it into a U-shape to look for any of the damage listed below. When inspecting rope anchors, grasp the device and twist it to check for unraveling or loose strands. You should also run your hands, without gloves, along the material of both types of anchor to feel for damage.

If you see any damage, including cuts, nicks, tears, pulled/missing/cut stitches, broken fibers, cracks, deterioration, user modifications, missing straps, knots, kinks, hockling, or popped/deployed fall indicators, remove the anchor from service. Fraying, abrasions, discoloration, hard/shiny spots, excessive hardness/brittleness, undue stretching, fibers that are burnt, charred, or melted, and uneven webbing thickness should be shown to the Competent Person to ensure the device is still safe for use. Mildew can be cleaned with soap and water.

Some pass-through anchors have wear pads along the loop to minimize damage to the webbing. Even if you notice significant wear on the wear pad, the anchor may still be in good shape. If you have concerns, ask your Competent Person.

Wire Rope/Cable

Wearing gloves, check for bird caging, broken wire strands, kinks, bent strands, rust, pitting, discoloration, or damage caused by corrosion or excessive heat. You can also look for crushed, flattened, or jammed strands, bulges in the cable, and any gaps between strands.

Hardware

Look for excessive wear, damage, rust, pitting, corrosion, rough/sharp edges, cracks, breaks, user modifications, and any other damage.

If you see any kind of damage, alert your Competent Person and take the anchor out of service immediately. They will then determine if it is still safe to use.

FAQs

How much weight does a fall protection anchor support?

The static load amount that anchors used for fall arrest must support is 5,000 lb for non-certified anchors or a minimum 2:1 safety factor on maximum arrest loads for a certified anchor. Fall restraint anchors must support 3,000 lb. According to ANSI regulations, anchors must also support the weight of a user between 130-310 lb. At FallTech, we test our anchors up to 425 lb. in some cases for workers weighing more than the ANSI capacity range. (Note: These ratings are for a single user, unless otherwise stated.)

Can you tie off to a scaffold for anchorage?

Some scaffolds are designed to safely support an anchor tie-off. In these cases, the manufacturer determines, designs, and tests its scaffolding for this use. Before using a scaffold as an anchorage, check with the manufacturer and rely on your Competent Person’s decision regarding this use.

What is the minimum safe working load for an anchorage point?

At minimum, the safe working load must be twice the load it is likely to support. For fall arrest, this means it must be able to support twice the maximum arrest force of a fall in that situation as required by OSHA. For work positioning or fall restraint, anchors must support two times the foreseeable force that it may experience.

What are mobile fall protection anchor points?

In some situations, workers need an anchor that allows them to move around the worksite. Beam trolleys have wheels that allow the device to roll along the beam, allowing the workers to move horizontally below it. Some “trailing” models of beam clamp anchor are designed to attach to the top flange of a beam and slide along as the worker moves.

Counterweight systems are set on top of a roof and anchored with a series of heavy weights. If workers want to move to a different position, they can carry each weight to the new area to recreate the anchor in that section.

Gantry systems, also called an “anchor point on wheels,” are often seen at airports and used for tasks such as working on the wing of a plane. These large frames can be rolled and locked into place, offering a secure overhead anchorage wherever they’re needed.

Why Choose FallTech for Your Anchors & Fall Protection Needs

You don’t buy fall protection gear just to check off a box on your compliance checklist. This equipment may save lives, so it’s important to find the products that give you full confidence in your workplace safety. At FallTech, our users’ safety is always the driving force behind our work. From anchors to harnesses, we treat each product as if it were being made for our own protection.

To ensure our fall protection equipment meets the highest safety standards, we test each product in our ISO 17025:2017-accredited lab. We also publish all of this data online, offering test reports, along with our Declaration of Conformity (DOC) documentation, for every item on our product pages. If you are worried or have questions about a particular application, we can provide a test report for that use.

Choosing FallTech means gaining a fall protection safety and compliance partner. Our sales team are fall protection experts, actively pursuing and sharing industry-leading information with others in our field. If you have a question about your products or need a system tailored to your unique needs, we will work with you to find the best solution. As a privately-owned company, we can offer a personalized experience to all of our customers, giving you the assurance you need to be confident in your workplace safety.

Explore our fall protection anchor products today to start building a system that empowers your team to work at their best without enduring unnecessary risk.

Body Wear

Anchorages

Lanyards

SRLs

Confined Space

Systems

Tool Tethering

Rescue and Descent

Kits

Utilities

Regular, thorough inspections are a key part of fall protection. Your equipment may be damaged in the field, because of improper storage, or after years of use. The only way you can be sure that your safety systems are working correctly is through proper inspections. Before every use, workers should do a pre-use inspection to check for any problems. Your Competent Person must also inspect all of your equipment at least once annually. Also, consult the user manual for the manufacturer’s recommended inspection schedule and frequency.

Regular, thorough inspections are a key part of fall protection. Your equipment may be damaged in the field, because of improper storage, or after years of use. The only way you can be sure that your safety systems are working correctly is through proper inspections. Before every use, workers should do a pre-use inspection to check for any problems. Your Competent Person must also inspect all of your equipment at least once annually. Also, consult the user manual for the manufacturer’s recommended inspection schedule and frequency.