Why do leading edge SRLs need an energy-absorbing component directly connected to the user’s body?

If the worker experienced a fall over a leading edge, the connector would kink over the edge. This would keep the shock pack added to the SRL, as discussed above, from absorbing the energy created by the worker’s body hitting the end of the line. The user would experience more than 1,800 lbs of arrest force, exceeding the OSHA-regulated limit and likely causing serious injury or even death.

If a worker experienced a fall over a leading edge, the lifeline would kink on the edge, preventing any energy absorbing device on the anchorage side of the kink from deploying properly and absorbing that fall energy. Without an inline energy absorber connected to the user’s body, two serious things can happen: (1)The user would experience more than 1,800 lbs. of arrest force, exceeding the OSHA-regulated limit, and likely causing serious injury or death, and (2) the initial force of the impact when the device locks up could sever the line on the edge, allowing the worker to fall untethered, likely causing serious injury or death.

With an inline energy absorber, the fall will be arrested almost like a normal lanyard would be if you were anchored on the edge where the cable is kinked. The energy absorber will also reduce the force on the lifeline, ensuring that it will survive the fall event.

When searching for leading-edge-rated devices, shock packs or external energy absorbers built onto the line constituent are the easiest ways to identify compliant devices, such as 30- or 50-foot SRDs. If it doesn’t have an integral energy absorber, such as large SRD devices without shock packs, it’s not compliant by default.

If you are using a personal SRL, however, the following applies instead.

4. Personal SRLs

Section 3.3.5 also states: “If the SRL-LE device housing is intended to be connected to the body support and can only be used in this orientation, then an energy absorber is not required as part of the line constituent.”

If the user will connect the SRL to their full-body harness dorsal webbing or hang it on their dorsal D-ring, you don’t need an energy absorber that is integral to the unit’s lifeline. Instead, personal SRLs like these should have the shock pack on the body-side of the gear so it will safely stop a fall over a leading edge with minimal injury. This will protect your workers and keep your workplace compliant.

ANSI Z359.14-2012 vs ANSI Z359.14-2014

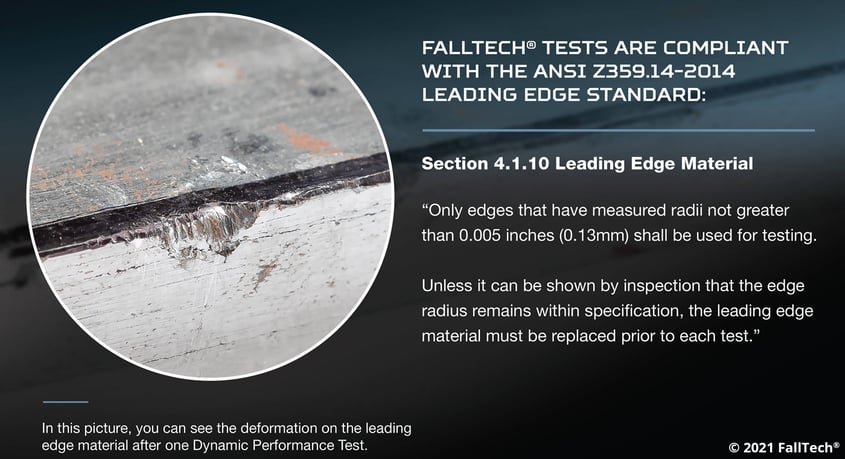

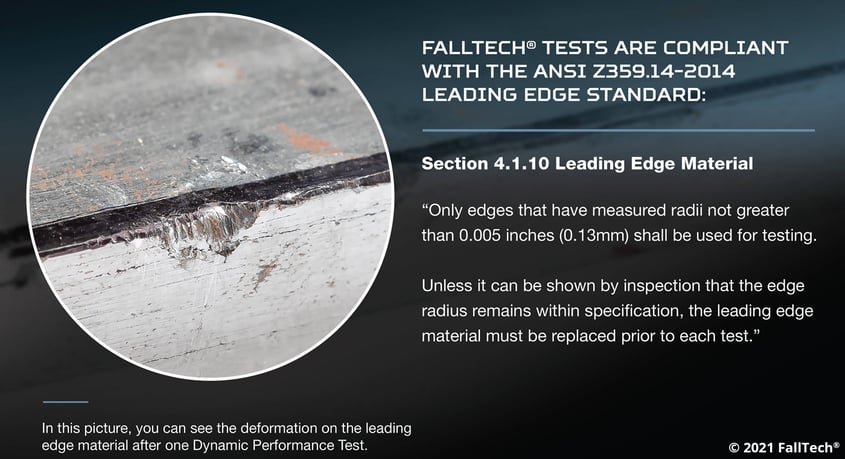

The ANSI Z359.14 standard changes with evolutions in hazard knowledge, work practices, and the development of new safety products. When the 2014 standard was published, for example, it contained one major change. The committee that created the ANSI/ASSE Z359 standard added specific requirements for the sharpness of the steel edge used in drop testing.

Now these edges must be razor-blade sharp with a maximum edge radius of 0.005”. This change ensures that leading edge SRLs are tested against the sharpest structural steel edges they may encounter at job sites.

During testing, the cables or webs hit this sharp edge with enough force to dull and damage the steel in a single drop test. Complying with the ANSI Z359.14-2014 involves replacing this edge for every test to guarantee that the equipment will perform dependably in any fall.

What kind of leading edge drop tests are required by ANSI Z359.14-compliant SRL-LEs?

To keep SRL-LEs compliant, manufacturers have to use two types of drop tests, Dynamic Performance Tests and Dynamic Strength Tests:

- The Dynamic Performance Test involves a test mass of 282 lbs and a post-fall, unrestrained swing for 10 seconds. After the drop, manufacturers also add an additional 675 lbs to the test mass.

- The Dynamic Strength Test requires a test mass of 200 lbs and a post-fall, unrestrained swing for a full two minutes.

Additional requirements include:

- Testing perpendicular to the leading edge with a lateral offset of five feet

- Testing in ambient conditions, hot conditions (minimum two hours in 130 degrees F with 85% humidity), wet conditions (minimum three-hour submersion), and cold conditions (minimum two hours in -40 degrees F)

Dynamic Strength Tests are more difficult than Dynamic Performance Tests, but the additional weight yields a higher minimum required fall clearance. Because of this, manufacturers may use Dynamic Strength Tests for all testing configurations. At least 12 leading edge tests must be performed to achieve ANSI Z359.14-2014 compliance.

Why is ANSI Z359.14 compliance important?

Following ANSI standards ensures that you address workplace hazards, something legally required by OSHA. Non-compliance opens you to liability, an increased risk profile, and potential punitive state and federal penalties.

More importantly, when you understand the specifics of the ANSI leading edge standard, you can also have confidence in the equipment you choose. Though the broader ANSI Z359.14-2014 standard covers these requirements, a device that is ANSI Z359.14-2014- compliant may not be compliant with leading-edge standards. The more you know about these stringent requirements, the more safe your workplace will be.

Leading Edge Safety: The importance of leading edge set back distance in foot-level SRL-LE applications - 0 ft vs 5 ft

Though we have spent a lot of time discussing standards, the way you use your leading edge fall protection system is also critical for safety. Specifically, we’re talking about foot-level tie-offs.

If you can’t use an overhead anchorage for your SRL, foot-level tie-offs are a common alternative, though they’re not ideal. When changing the location of your anchorage from overhead to a working/walking surface, however, you now have to address an increased fall clearance hazard that arises from the now-extended free fall.

In this case, the set-back distance of the anchor (or how far the anchor is from the leading edge) is critical to achieving the minimum-required fall clearance (MRFC). For maximum safety, you should use a set-back distance of five feet. You can increase this distance, but it won’t improve the performance of an ANSI-compliant leading edge SRL.

You should use a five-foot set-back distance versus an anchorage at the leading edge because it equips your fall protection system to arrest the fall more quickly. If your anchorage is at the edge, the SRL will create additional freefall distance as it retracts. The pawl mechanism also needs the lifeline to pay out fast enough to engage. With a zero-foot set-back distance and below D-ring foot-level tie-off, it won’t activate until the worker has fallen below the device hanging beneath the leading edge, further delaying the arrest.

With a five-foot set-back distance, this pay out begins as soon as the user’s D-ring passes below the level of the anchorage. You can eliminate the extra freefall length, lowering the MRFC, and creating a safer working environment.

How to find safe and compliant leading edge SRLs

You may find SRLs that would withstand use on a leading edge, as defined by OSHA, but that doesn’t mean it’s capable of protecting your workers in a fall. If you want to prioritize safety, only use SRDs that meet the gold standard of the ANSI Z359.14-2014 leading edge requirements. Use the information in this blog as a starting point when choosing your equipment. Do you research to understand the manufacturer, equipment, ISO Testing Scope or testing laboratory credentials, and test reports for every product you consider. When you have proof that your SRL-LEs will meet performance claims, you can have confidence in leading edge fall protection gear that may save lives.

Why Choose FallTech for Your Fall Protection Needs

FallTech’s industry-trusted, American-made fall protection products are one part of a broader commitment to helping our customers be as informed and empowered as possible. When you choose FallTech, you connect with a sales team that has in-depth knowledge about fall protection. We work directly with our customers to understand what they need and how we can help them achieve it.

As a privately-owned family business, we move faster and are more flexible than our larger competitors. Have a pricing request? Need a consult about your fall protection requirements? We can give you a quick answer, personally working with you to resolve your needs.

Transparency is another way we work to serve you. We publish all of our product test results and data to give you confidence in our equipment. You can also find declarations of conformity for all of our products to confirm that each meets both OSHA and ANSI requirements. With our own ISO:17025 Lab and ISO:9001 QMP, we ensure the consistency and quality of every product.

Most importantly, our service doesn’t stop with your order. We know that safety is your top priority, so we offer a variety of support options to help you build the best fall protection program. Reach out to us for advice about novel situations and we will happily find the ideal solution. Tour our facility to learn more about our products, visit our website for additional resources, or sign up for our comprehensive training sessions.

When you need a company you can trust, FallTech is your fall protection solution.

Explore our range of fall protection equipment to find the systems designed specifically for your industry, work, and needs.

Body Wear

Anchorages

Lanyards

SRLs

Confined Space

Systems

Tool Tethering

Rescue and Descent

Kits

Utilities

The latest iteration of the standard will be adopted in February 2023. It is expected that the updated standard in 2022 will eliminate the SRL-LE designation to be superseded by SRL (SRL Class 1 overhead devices or Class 2 leading edge devices.) Additionally, SRL-P will designate Self- Retracting Lanyard, Personal. The SRL-R definition will remain unchanged.

The latest iteration of the standard will be adopted in February 2023. It is expected that the updated standard in 2022 will eliminate the SRL-LE designation to be superseded by SRL (SRL Class 1 overhead devices or Class 2 leading edge devices.) Additionally, SRL-P will designate Self- Retracting Lanyard, Personal. The SRL-R definition will remain unchanged.